MorganTyre

-

Posts

291 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by MorganTyre

-

-

PotC 4

in Pyrate Pop

I saw it the other day. The 3D effects were ok but I think the luminosity loss due to the glasses robbed a bit from the dramatics of the scenery itself. I am so glad that did away with all of the old characters. I think all of the comedic possibilities of those one sided characters had played out in the first movie and the second and third just featured retreads of the same old material. My biggest disappointment was just how far they departed from the original book. For those who have seen this movie but have not read the book please do yourself a favor and read it. Other than Blackbeard and the fountain there is literally nothing in common with the source material that "suggested" the script. Because of that departure the zombies feel forced as did the magic "Revenge". Unfortunately, all of this means that a faithful to the book movie will never be made which is a shame.

Once you separate the movie from the book the movie does have some neat scenes. The mermaid introduction for me was the standout and not the London escape. The legless Barbossa was a neat effect though I agree his makeup was overdone. He looked more rotten than the zombies. One minor quibble (that drove me nuts and literally noone else in the civilized world should have noticed) was that one of the zombies (don't remember his name but he had the majority of the screen time) had modern snap shackles, modern bow shackles, and what appeared to be a caulking iron strapped to him, literally none of which made sense and most were completely anachronistic.

All in all it was a fun movie for what it was but I think the best thing they could do to that franchise is get rid of Elliot and Rossio as writers.

-

Well it's been a wild and crazy year for me so far. Sorry for the long absence from the pub here. Now that the rigging and dive work is starting to slow down I'm back to producing tools, cordage, etc. for sale. I also finally have a website up (sort of) showcasing some of the work, most of which regulars to the pub have probably already seen. Pricing is listed but right now it's just phone or e-mail orders. The home button on the bottom of the page takes you to my rigging/dive company here in south texas. It's a work in progress but it's finally getting there.

-

There is a lot of good advice here, and I thank you all. I believe the plan of acyion I am going to take is a few boards across the center and under the ropes, it`seems to be the best option, they should flex a bit but give some support to the sides. If that doesn't work then it is going to be 4x4 for the side boards, heavy but effective.

Some bowing is to be expected. I wouldn't worry about the amount pictured. Take one of the side boards, stand it on it's side between two blocks. If it can support you standing in the middle without breaking then you have plenty of safety margin (since in practice your weight is being somewhat evenly distributed between the full length of the four side boards rather than point loading one board. Oak was overkill to be honest though very cool. Mine is cedar which is a pretty weak splintery wood and was half cracked though on one board due to a knot (before I replaced it) and was still plenty stout. Since replacing that board I've had probably 400 lbs on it without issue and I'm sure it can take more. All of that said, you're ropes are probably going to sag low enough to put your butt on any boards slung underneath. You might consider making a shallow U shaped support to clear the sagging ropes. To save weight I'd take a 1x8 or 1x10 of yellow pine and cut it to shape with a jig saw. It's under compression only so something that size is more than enough. I'm about to make another one - this time a "castaway" bed made up crudely of driftwood.

-

Does anyone know how to do this to a brass hilt? Will the same concept work with that, or is it really best for steel?

Here's a site with some good instructions for aging brass. I've done the ammonia trick and it works well.

-

I've had great results with naval jelly on steel. Apply a thick layer, let it sit for a short bit and then clean it off completely.

-

Where are they doing their thing? I live here in Corpus and wasn't aware there was any buccaneer activities going on for buc days. Nearest place to actually buy powder is in San Antonio I believe.

-

The only serving mallet I have is one I made for a project some time ago. It's extremely handy though. Now that you mention it I may have to make another.

-

Here's some stuff off my new lathe. Pictured are three seam rubbers (one in poplar and two in mahogany), two small fids (mahogany and maple), a needlecase (mahogany and pine), and a mahogany belaying pin for 3/8" line.

-

how do you determine the length of the end piece. in otherwords, if you start with X feet of untwisted line how many finished feet do you end up with? I know the length of the walk could in theory be indefinite, but whats a good minimum ammount of room to set something like this up?

You do lose a certain percentage but how much depends on the diameter of the line, the stretch, etc. I'm sure there's a formula but it's going to be in the neighborhood of 5% or less. I normally set it up inside my shop which allows for approx 25' finished pieces but the are easy to set up temporarily so doing it outdoors is easy. I've done stretches well over a hundred feet and have room to produce about 250'. Because everything is small and lightweight you don't need a permanent set up, just drag it out when you need it. Next time I do I'll do some before and after measurements.

-

IIRC, you crank at one end, hold the other stationary, use the cross pieces to help "guide" the twist...

with this set up, one could lay the yarns right, lay the rope left ( i think that's correct ) the stationary end moves as the rope is shortened by the twisting, i think...

is that the correct way, morgan ??

Yep, that's more or less it. The one end is cranked and turns all of the strands in the same direction. On my setup the end opposite the rope making machine is on a very free spinning swivel which is tied to a line which leads through a block and is then weighted. That's to keep a constant tension on the line while still allowing it to shorten which it'll do as it twists. The cross piece (or clover - depending on the number of strands) holds the strands apart. As that piece moves towards the machine the rope will form itself behind it. The swivel allows the rope to spin freely itself so you don't need another turning crank at the other end. The machine I build uses wooden gears which I hacked out of an old sunfish daggerboard using a template I generated here http://woodgears.ca/gear_cutting/template.html which spins some home forged hooks. It's not authentic by any means but works handsomely. On the smaller diameter lines I typically make it's not unusual to crank that handle a thousand times and the wood is still holding up just fine. I grease everything with Lanocote. It'll produce line up to an inch or so but I use it primarily to make hard laid cotton, flax, and hemp line for fancywork.

-

I built my own ropewalk a month or so ago and have used it quite a bit. Any help or info I can provide I'll be happy to.

-

Trying out the Kraken rum - on the rocks. Not bad and getting better by the glass.

-

Yes, voodoo was the primary driver in the movie (the fact that they were all pirates was completely secondary) So much so that it was even used to explain the Port Royale earthquake. It's also used to explain of the real life exploits of Blackbeard.

I should have said that voodoo is the primary driver in the book.

-

Yes, voodoo was the primary driver in the movie (the fact that they were all pirates was completely secondary) So much so that it was even used to explain the Port Royale earthquake. It's also used to explain of the real life exploits of Blackbeard.

-

Huh... well, the more I hear the less hope I have that this will resemple Tim Powers' On Stranger Tides in any way whatsoever...

Yeah, I agree. The more I hear the less it sounds like the book. A real shame too because the book itself is such great fodder for a movie and this one being made guarantees it never being done right. Still, it may be an entertaining movie on it's own merit and I do likes me some mermaids. Curse the PG/PG-13 rating for not letting them be done right.

-

Two small points to add:

Rigging knives are, as a rule, pointless. Not with the tips broken off to prevent stab wounds, but made without a point for practicality (what use is a point on a rigging knife?)

Just been reading a piracy trial account which mentions the pirates cutting up oars to use as cudgels in lieu of any other weapons, so no, not all pirates carried swords.

I'll add to that that rigging knives are generally very thick along the back. The most common way of cutting line of any size is to lay it across something, rest the knife down on it, and then strike the knife with the palm or a marlinspike. If you are good you should be able to cleave right through the 99% of the line without touching the spar or rail beneath. And as someone who does it regularly, I can say that it's about the cleanest and most efficient way to cut even modern lines. The thick blade is necessary to take the abuse.

-

Went to the J.M. Davis Museum (about which more later) for my birthday, and in their library got my hands on an out-of-print copy of Frankland's Small Arms of the East India Company. It has a section on the small arms of the East Indiamen, which the Company regulated even though it didn't own most of the ships. Records are unavailable from the Golden Age, but here's an interesting list of the East Indiaman Sullivan's arms loadout from 1783.

60 brass-mounted muskets

30 bayonets with scabbards

15 pair of pistols, .56 caliber.

6 brass-mounted walnut musketoons

6 swivels

60 cutlasses with scabbards

80 cartouche boxes with belts and frogs

25 pole axes

A hundredweight of musket and pistol balls in kegs

A brass bullet mold

400 musket flints

200 pistol flints

4 scouring rods, 1 breech wrench, 1 spring hook, 1 melting ladle

20 spare musket rammers and 10 spare pistol rammers and 12 formers for cartridges

40 lock nails, 35 side and breech nails

12 spare triggers, 6 pipes, and 6 worms

Frankland, Small Arms of the East India Company, vol. 2, p. 576.

This is the first time I've ever heard of pole axes being used on a ship.

I'll add that there is no references to pikes or boarding axes, both of which were very common in that era. Looks like they were intending the poleaxe as a catchall.

-

And how much does one of those cat's cost?

I currently have a couple of wooden handled ones for $20. They're at the shop so I'll have to snag pictures tomorrow. All the cordage on the whip came out of my rope walk. The tails are flax and have wall knots at the ends. There's a large turkshead of hard laid cotton at the top. All of the handle is coated with pine tar. Custom work and all knotted items like the one pictured are PM worthy but prices are reasonable. Give a shout if you are interested or curious.

-

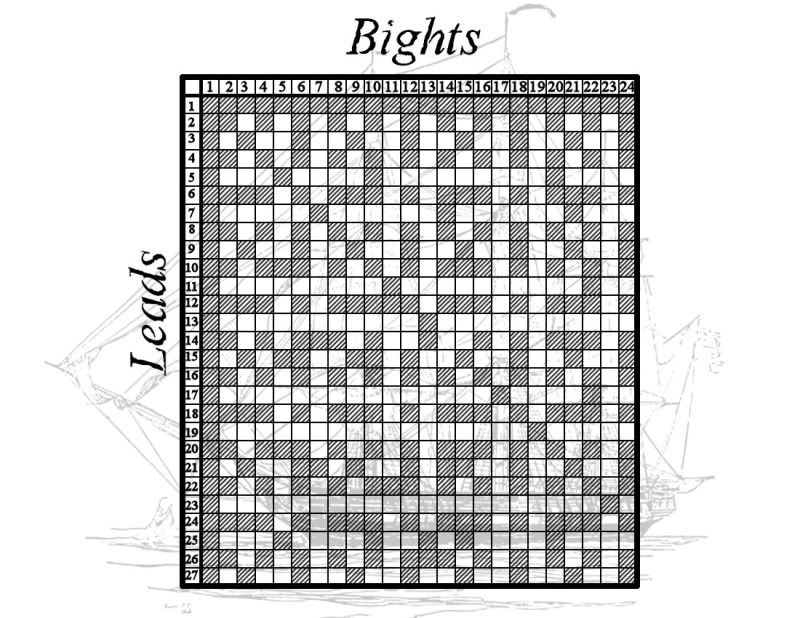

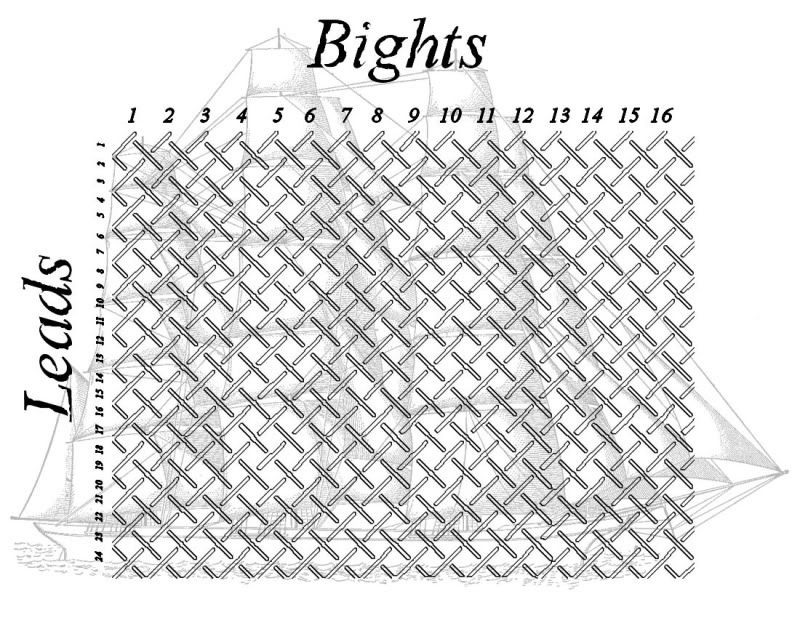

I recently produced the following two charts for use in my shop and thought I'd share them here. These are to produce a regular over one/under one weave in as large or small a turkshead or mat as you'd like from one continuous piece of line. A description of use follows each picture:

We pretty much all know how to tie the most common turkshead - the 3 bight x 5 lead in hand but what other sizes are possible? To use this chart, read the bights across the top then follow down the column to the number of leads you are looking at. If the space is blank then this is a possible turkshead. If the space is shaded out then it is not. For example, Lets say you are tying a particularly wide turkshead over something relatively narrow such as a tiller so we figure something about 4 bights by 24 or so leads. A look at the chart tells us that a 4x24 is not possible but a 4 x 25 is so that's what we'll do.

This chart shows you the basic over under weave pattern for turksheads and mats as big as 16x24 (which according to our first chart is not actually a possible combination) The easiest use of this chart is to print out or duplicate a section of this chart that contains the turkshead we're wanting to make, wrap it around the item in question, pin the bights, and then make the knot directly over the picture following the over/under sequence illustrated. I'll do a small mat tutorial showing these two charts in use this afternoon.

-

Salty Dick claims the Crabfish to have been first published in 1620 and is still around to some degree (I personally first heard it a dozen or so years ago from a sailor friend).

-

Not in the near future but at some point possibly. What sort of material would you be looking for? That is something I can deal in in manilla. Last batch I had went to a korean baptist church as a tug of war rope. Only problem is that shipping is a killer. Still, if you really do need some I can get it your way. Just not making anything that big yet.

-

Well, my ropewalk is up and running so now I'm offering custom cordage for all your needs. Sizes up to 3/4" are currently available from a variety of materials (jute, sisal, manilla, flax, nylon, hard laid cotton, etc.) PM for quote. Pictured below is some 3/8" flax which would sell for 25 cents a foot or so. I'm also bottling and selling my "Square rigger" pine tar based finish that I use on quite a bit of my work but I'll have to look in to whether or not it would be hazmat to ship. I plan to have better sample pictures up asap as well as a youtube video of the process in action.

-

Another one I've seen recently is a really cool clamshell hilt cutlass that this guy is selling through No Quarter Given for around $75. I don't know how to contact him directly, but you can talk to NQG about it.

Does anyone have a picture of this one?

-

Wow, great charts. Those are certainly on my want list now.

Old boat, 42 foot gaff ketch

in Thieves Market

Posted

Wooden I assume? What's she built from? When was the last survey?